Yippee! I have a new toy!

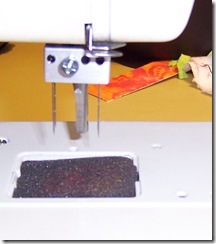

Ok, I have a reconfigured-converted-really-old-but-practically-free-and-only-slightly-dangerous machine for needle felting!

Here’s the story: after cleaning and organizing my craft room a while back, I made a promise to myself that I wasn’t going to buy any more supplies until I used up (at least some of) what I already had. I can still take classes, but only if I already have all the supplies; and even if I don’t, I have to make do and improvise with what’s on hand. The only thing I’ve allowed myself is fabric, and that’s because I didn’t have much (really!), and I’ve got lots of plans for pieced quilts in the near future. And I’ll miss the Houston quilt show and won’t be able to stock up. And I found some really good sales on good-quality fabric. Really.

So anyway, I was telling a friend how I was looking for an old sewing machine to convert to a felting machine (so I could use that wool and silk roving, of course). And she happened to mention that she had an old Brother machine that didn’t work, but that I could have it if we (meaning my incredibly mechanical partner) could fix it. She didn’t know what was wrong with it, she said, but she had lent it to someone else who “couldn’t get it to sew right.”

I’m guessing the not-getting-it-to-sew-right problem was tension- or needle- or thread-related, because the motor worked just fine, and that’s the only part I was really interested in.

So I ordered a conversion kit online (ok, I said it PRACTICALLY free) for $50, and last night my sweetie set about dismantling the sewing machine and remantling it into a felting machine. There was a lot of banging and greasiness and one minor incident of needle-pricked fingers (hers), and then she was done!

This conversion kit doesn’t come with any sort of needle guard, but we (ok, the mechanical half of we) think we can rig something up and attach it to the presser foot bar. And yes, in the meantime I'm being VERY careful not to needle-punch my fingers, and I'm definitely not allowing the grandkids to use it.

When I tested the machine out last night, I was very disappointed that the fabric “dragged” on the foam. The fabric was actually felting TO the foam, a problem I hadn’t considered. I looked everywhere online to see if someone else had had that problem, but couldn’t find anything. I finally went back to the installation instructions and found an oblique reference to the problem of not having enough “control of the fabric” if the needles were going too far down into the foam. To gain “more control,” the instructions said, just raise the mechanism higher on the bar. Of course, that didn’t work, since the mechanism is as high as it can go on the bar and still allow the wheel to spin, so I pondered the problem all night, in between thinking/dreaming about all the stuff I could needle felt. Around 4 am, I realized that if you can’t raise the mechanism, you have to lower the foam. Problem solved!

This morning I gathered some of my “supplies” together—wool and silk roving, thread, yarn, sheers, felt, etc.,

and proceeded to play:

(yes, I know, very ugly, but we’re going for technique here, not design). I tried felting on plain habotai silk, which gives it a really cool rouched or gathered look; then I threw on wool roving and yarn to see if it would stick. Next, I took a piece of acrylic (craft) felt and started felting wool and silk roving onto it, then added more yarn and more roving:

Lots of fun! I think I’m going to do some stitching on the “flowers” with my sewing machine, then cut them out and add beads to the center and . . . I don’t know, maybe applique them to something.

Then I’m going to try to remember all those cool projects I kept running across that caused me to think, “I really NEED a felting machine!” If you know of any, feel free to send them my way!

3 comments:

Seriously? A conversion kit? Where? How hard was it the "mantle"? I have a spare machine and want an embellisher BAD!

I sent this by email but I'll put it here too, in case anyone else is interested:

Well, I guess it depends on how mechanical you are; I'm not at all mechanical, but my partner can figure out most things. I watched her work on it, and basically you just pull anything metal out that is under the needles; this included unscrewing all the screws she could find to remove the bobbin case, and removing this shaft thing that took some hammering. It's SUPER easy to put it back it together; you just screw the attachment on where the needle goes, and put some foam in the bottom compartment where the bobbin case was. I think we can find/buy a plastic finger guard that will attach to the presser foot bar (so don't remove that piece--it doesn't interfere with the felting attachment, at least on my machine).

Here's a link so you can see the attachment:

http://www.feltcrafts.com/needle-felting-machines.htm

I actually bought my attachment (which looked exactly like this) from a guy on ebay, and it was the same price. He provided good directions for putting the attachment on, but no instructions for removing the old parts (I guess that makes sense, since there are too many machines to cover).

I can't begin to tell you how THRILLED I am with it! It works great and I'm felting away like a fool. I definitely thinks it's worth the $50 for the part, even if you have to beg/borrow/steal a mechanical person to convert the machine :-)

Thank You for your prompt and concise response! I am going to check this out...I have coveted an embellisher for a long time...this is an affordable way for me to have one. THANKS AGAIN

Post a Comment